Guest post by: Fraunhofer IAP & Fraunhofer CAN

"People push towards the light, not to see better, but to shine better" - Friedrich Wilhelm Nietzsche (1844 - 1900)

Quantum dots (QDs) represent the latest generation of hybrid inorganic-organic nanomaterials. They form a triad of inorganic nanotechnology, organic semiconductor technology and solution-based processability. The emission properties of inorganic, luminescent nanoparticles depend directly on the particle size. This size quantization effect makes it possible to control the band gap and thus the emission color of semiconductor materials. The target parameters are a high quantum yield of the luminescence as well as high stability and environmental compatibility.

The display market is primarily characterized by LCD and LED-based systems. The OLED displays are currently developing into the next generation. Today we find OLED displays primarily in smartphones, tablets and televisions.

So far, semiconducting charge transport materials, organic dyes, organometallic compounds and organic or inorganic intermediate layers have been used, which are mainly deposited with the help of vacuum processes. These processes are complex, characterized by high material consumption and therefore not efficient.

In the display industry, there is a noticeable trend towards using substrate materials with even larger areas. However, this will only have a positive effect in the long term if the materials can also be deposited more easily and efficiently. For this purpose, solution-based processes are being developed. So far, special organic molecular structures have been used for each emission color in the display, some of which are complex to produce.

With the use of QDs one can overcome this disadvantage. QDs could thus be the next generation of emitter materials in OLED displays. Research at Fraunhofer IAP in the field of QD-LEDs and OLEDs focuses on the development of QD and OLED materials and printing technologies for applications in the field of displays, signage and lighting, while Fraunhofer CAN is focusing on the development of QD material using their proprietary continuous flow technique.

Nanoparticles play a major role in research at the Fraunhofer IAP and Fraunhofer CAN. The area of quantum dots (QDs) has a high innovation potential and significantly expands the portfolio of the Fraunhofer-Gesellschaft in the field of materials research. Research activities cover the whole spectrum from tailor-made QD synthesis to solvent processed devices to full characterization. Addressed applications are films for color enhancement, photo-luminescent QDs for color conversion and electro-luminescent QD-LEDs.

QD synthesis

With QDs, all colors in a display can be realized with a single material. The targeted adjustment of size and size distribution of the nanoparticles are the greatest challenges in QD synthesis.

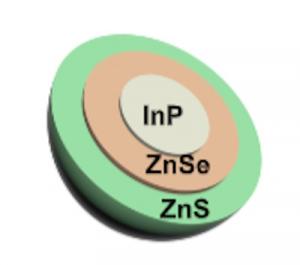

The Fraunhofer IAP and Fraunhofer CAN have been engaged in QD design and synthesis for several years and gained attention on an international level. They have been covering different aspects in QD design such as multi-element cores like InPZnS and ZnTeSe, multi-shell architectures like in CdSe/CdS and InP/ZnSe/ZnS quantum dots, but also doped core and doped shell approaches.

Fraunhofer IAPâs multishell approach of InP QD.

Fraunhofer IAPâs multishell approach of InP QD.

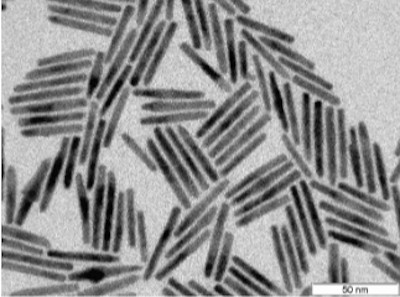

They have also made contributions to the development of mixed shells and gradient shells. A very important aspect is the shell thickness, e.g. mono layer shells vs. giant shells consisting of several mono layers, and how it influences the stability and performance of a given QD system in a certain environment. Fraunhofer CAN is also exploring the influence of the QD shape on their emission properties synthesizing zero, one and two-dimensional particles. Interesting properties, like polarized emission can be achieved using these complex structures.

Fraunhofer CANâs Nanorods © Fraunhofer CAN

Fraunhofer CANâs Nanorods © Fraunhofer CAN

Another aspect that Fraunhofer IAP has been working on is ligand design and modification. They have been investigating the influence of very short hydrophobic ligands vs. long hydrophobic ligands on QD and subsequently device performance. Also different ligand structures, such as aromatic ligands have been applied to Fraunhofer QDs either during the QD synthesis or in a post-synthesis ligand exchange. These concepts have been applied to QDs made of different materials to access different wavelength regions, such as ZnSe for blue, CdSe and InP for red and green and CuInP as well as PbS for IR emission.

Another important aspect is the approach to these materials via a simplified reaction scheme for easier application and scaling in an industry environment. This includes investigations on solvent-free one-pot synthesis approaches as well as continuous-flow reactor developments. In addition, we are actively looking for synthetic approaches that avoid problematic chemicals like HF and complicated synthesis setups.

QD color enhancement

Fraunhofer IAP is developing backlight films using quantum dots (QDs) as a color enhancement material for LCDs with a large color gamut. For this purpose, quantum materials can be synthesized on a large scale and with good reproducibility at Fraunhofer CAN. The Fraunhofer IAP specializes in embedding quantum materials in lacquers and other polymers. Scattering particles, e.g. titanium dioxide, improve light extraction. By direct mixing of QDs in one layer, they achieve combined green and red emission. The QDs concentration ratio defines the white point. With separate green and red layers, displays achieve even better efficiency. Here the layer thickness is an additional spectral adjustment parameter. Currently Fraunhofer IAP is developing structurable photoresists.

QD color converter

![]() Photo-luminescent red and green quantum dot pixels, printed with highest resolution by electrostatic printing on ITO glass © Fraunhofer IAP

Photo-luminescent red and green quantum dot pixels, printed with highest resolution by electrostatic printing on ITO glass © Fraunhofer IAP

Another development at the Fraunhofer IAP are highly efficient QD color converters for displays. Color converters transform the blue device backlight instead of just filtering white backlight. For this purpose, QDs are being developed that have a high level of absorption in the blue spectral range and which convert blue light very efficiently into green and red light. Good structurability is particularly important here, which can be achieved using the latest printing technologies such as electrostatic printing (ESJET/EHDJET). The latest achievement at Fraunhofer IAP are separately printed droplets with a diameter of 10 µm and a pitch of 15 µm without any guiding bank structure. This pitch enables solution processing of displays with more than 500 ppi in legacy layout.

Electroluminescent QD-LED

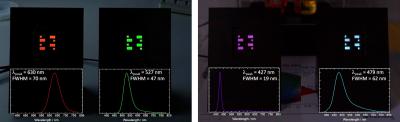

Electro-luminescent red, green and blue QD-LED devices with 4 mm² and 18 mm² segments, each ©Fraunhofer IAP

Electro-luminescent red, green and blue QD-LED devices with 4 mm² and 18 mm² segments, each ©Fraunhofer IAP

Developing high-performance QD-LEDs based on InP, ZnSe and ZnS is very important to bring QD-LEDs into future markets. InP-based QDs are among the most promising materials for green and red emission in displays, which approach the BT.2020 color gamut. Optimizing charge carrier balance and the recombination zone in the multi-layered device structure is key for the development of highly efficient and stable QD-LEDs. The Fraunhofer IAP develops new concepts for the electronic coupling of quantum materials to matrix and charge transport materials in order to enable better charge transfer. Based on the energy levels of the quantum materials, they synthesize suitable hole and electron transport molecular structures as well as matrix systems for optimal integration of the quantum materials. Those systems enable new processing methods. Based upon Fraunhofer IAPâs knowledge in solution processing of OLEDs, they process the quantum materials with inkjet or ESJET and develop corresponding inks.

Recent studies at Fraunhofer IAP on the stack design focus on an inverted structure, where they print the ZnO-based electron-transport-layer first. This structure provides higher luminance, comparable or better efficiencies and significantly longer lifetimes compared to the conventional structure. In addition, inverted QD-LEDs show a very high maximum luminance (> 20,000 cd/m2 ), which is of the highest values ever achieved with InP-based quantum dots. For very sharp blue emission, Fraunhofer IAP is developing ZnTeSe/ZnSe/ZnS based QDs.

Based on their materials and printing processes, Fraunhofer IAP and Fraunhofer CAN pave the way to fully ink-jet printed QD-LED displays.