Researchers at Daegu Gyeongbuk Institute of Science and Technology (DGIST), Ulsan National Institute of Science and Technology (UNIST), and the Institute for Basic Science (IBS) have developed a new method, called double-layer dry transfer printing, to create highly efficiency QD-EL displays.

The researchers say that with the double-layer dry transfer printing technique, the light-emitting and electron-transferring layers of the device can be transferred onto a substrate simultaneously, which reduces interfacial resistance in the device, which facilitates electron injection and the control of leakage charge transport during the fabrication process. The researchers, by minimizing the leakage current, managed to increase the EQE of the QLED device to 23.3%, up from around 5% that is achieved with normal dry transfer printing.

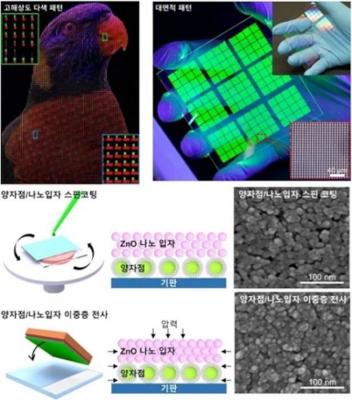

As part of the research, and by surface engineering of viscoelastic stamps, the researchers used the double-layer transfer printing technique to create RGB pixelated patterns with 2565 pixels per inch (PPI) and monochromic QD patterns with about 20,526 PPI.